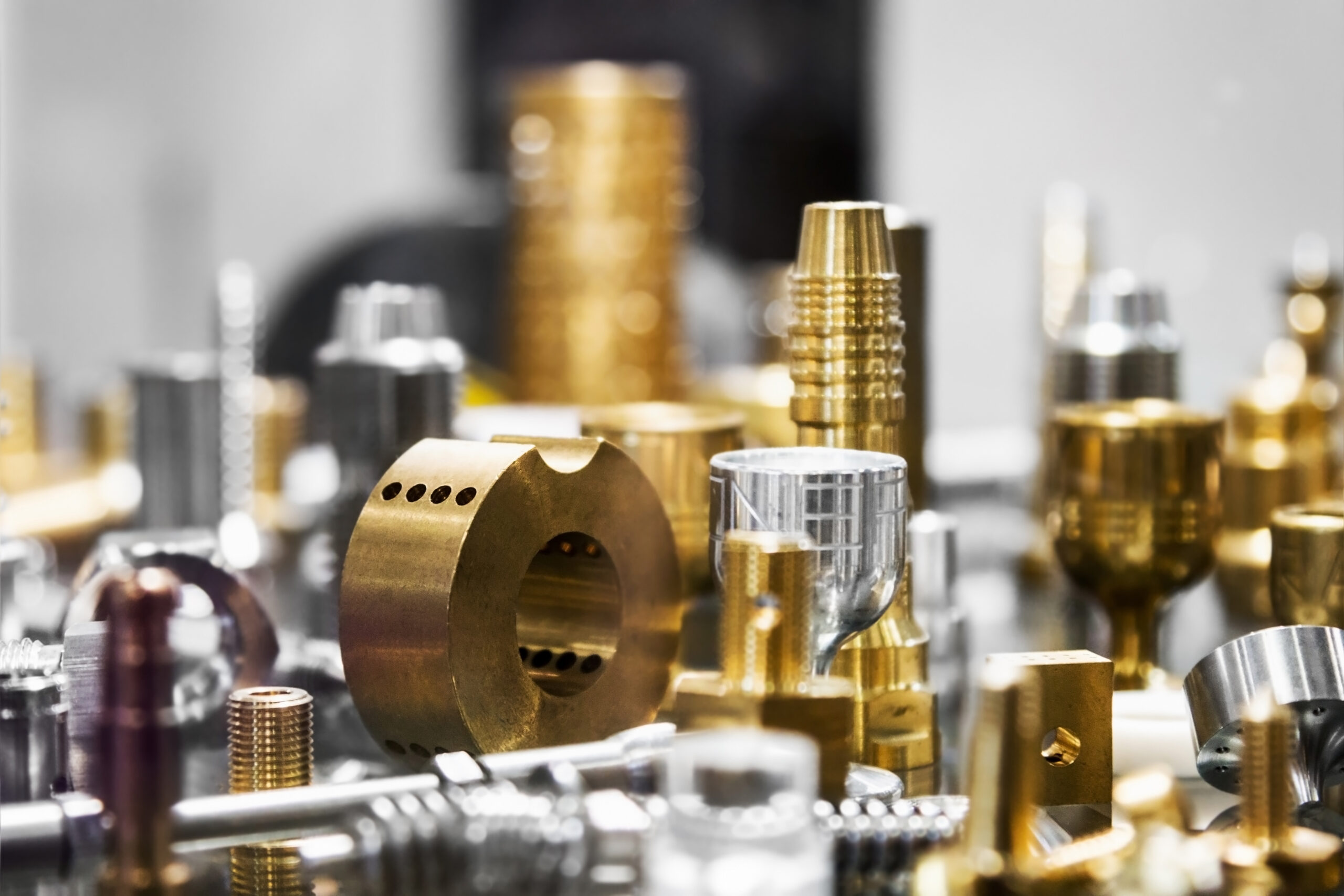

CNC turning is one of the primary methods for manufacturing precision metal parts, as well as Swiss turning – a specialized form of the turning process. Combining our turning processes with CNC milling services and multi-axis machining, Rapid Precision Manufacturing is able to produce virtually any custom metal part, accommodating both complex geometries and extremely close tolerances.

Customers who are new to the world of CNC machining often wonder about the advantages of CNC turning vs. milling – what makes one process better than the other? and what are the most suitable product applications? Below, we explore the CNC turning and Swiss turning processes to answer these questions and help our customers better understand their options for the manufacturing of custom-machined components.

CNC Turning Explained: How It Works and Common Applications

CNC turning is a precision machining process optimized for producing round or cylindrical parts, which are axially “turned” at extremely high speeds and machined by contact with computer-controlled tools. Through CNC automation, the cutting tools carefully remove only the required material from the rotating workpiece, leaving behind the desired part geometry and/or uniquely machined part features.

By analogy, a basic CNC turning machine can be compared to a pottery wheel: the wheel spins a ball of clay at high speed, while the potter gently shapes the material by hand. CNC turning applies a similar process to metal parts – with speeds that can reach thousands of rpm and high-powered metal cutting/forming tools that are robotically controlled with absolute precision.

An Overview of the Swiss Turning Process

Swiss lathes function very similarly to conventional CNC lathes. The main difference is that a sliding headstock feeds the bar stock through a guide bushing – opposed to clamping the workpiece on one or both ends in a conventional lathe.

The moving headstock in a Swiss lathe more rigidly supports the bar stock as it is machined, clamping the material closer to the tooling area. This provides increased stability which minimizes deflection and manufacturing errors, thus maximizing precision and consistency.

Additionally, conventional CNC turning processes only rotate the workpiece in a fixed position, whereas Swiss machines can perform turning operations and move the bar stock back and forth along the Z-axis. This lets us integrate various live tooling operations into the process such as drilling, tapping, or slotting, offering even more options for complex machined part features.

The Advantages of CNC Turning vs. CNC Milling:

- Optimized for round or cylindrical custom machined parts.

- Able to achieve perfectly round part profiles – much more difficult and time-consuming with other CNC machining processes.

- Swiss turning provides even more manufacturing flexibility, substantially reducing turnaround time for turned parts with additional complex machining features.

- State-of-the-art computer-controlled turning systems provide extremely high precision, accuracy, and repeatability.

Precision American Manufacturing Services Since 1997

Established in 1997 in Britton, South Dakota, RPM is a single-source American manufacturing company specializing in full-service CNC machining solutions.