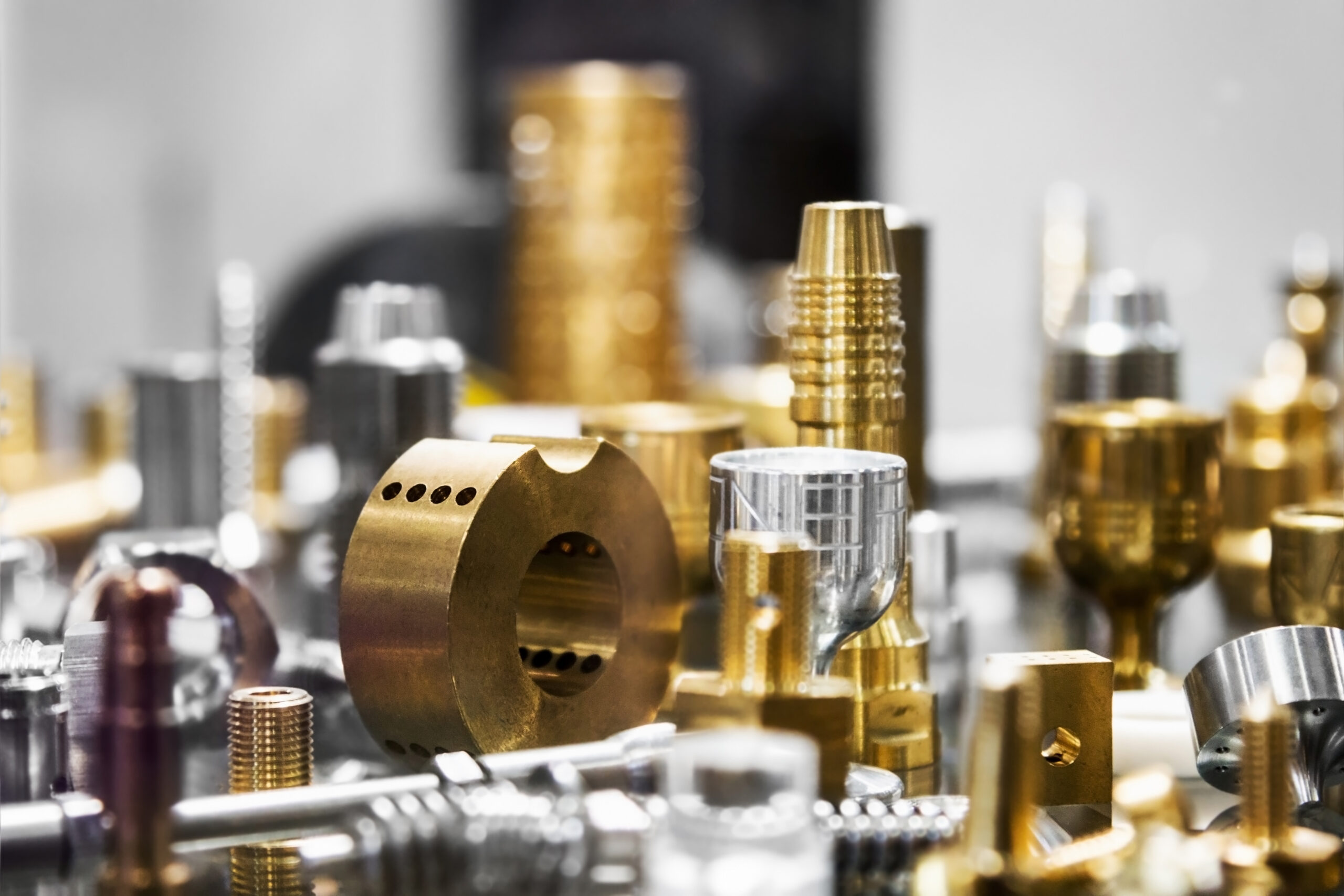

Rapid Precision Manufacturing takes a proactive and transparent approach to quality assurance when it comes to our machining facility. All of our processes have a foundation in careful quality management, and we tailor each one to ensure that the final product meets or exceeds customer expectations. And that’s especially true when it comes to our Swiss turned parts.

Swiss turning is a manufacturing process known for its ability to hold extremely tight tolerances, even on miniature components. It’s one of the most precise CNC machining technologies available in the industry and requires an expert operator to oversee the machine. And like our other machining capabilities, our Swiss turning services are subject to a rigorous quality management system for quality assurance with each project.

Quality throughout Production

RPM’s team integrates various quality inspections and control checks at each step of the process. Our team will carefully analyze your design and part specifications to help determine what the appropriate machining processes and materials are to make your part. We also inspect any incoming materials to ensure that they’re up to standard for your parts.

During machining, our team regularly spot-checks random part samples to make sure that they are in compliance with our high production standards and the requirements set and agreed on by our customers. Once operations are complete, we also have a variety of quality control equipment to evaluate and quantify the quality of the parts we produce.

Certified for Quality Management

In addition to strict quality control checks throughout our manufacturing processes, RPM also maintains a quality management system certified to ISO 9001:2015 standards. The ISO certification is a worldwide recognized set of requirements for a quality management system, used to demonstrate a manufacturer’s ability to provide consistent quality throughout their products and services, and their ability to meet customer and industry regulatory requirements.

The process of being ISO certified isn’t a one-and-done thing. RPM commits itself to a yearly inspection by a vetted third party to ensure that we remain in compliance with the most up-to-date ISO standards. Our certification shows our dedication to quality each and every day, and in everything we do.

Interested in partnering with RPM?

If you’re interested in our services, don’t hesitate to head over to our website to learn more about what we can do and request a quote.