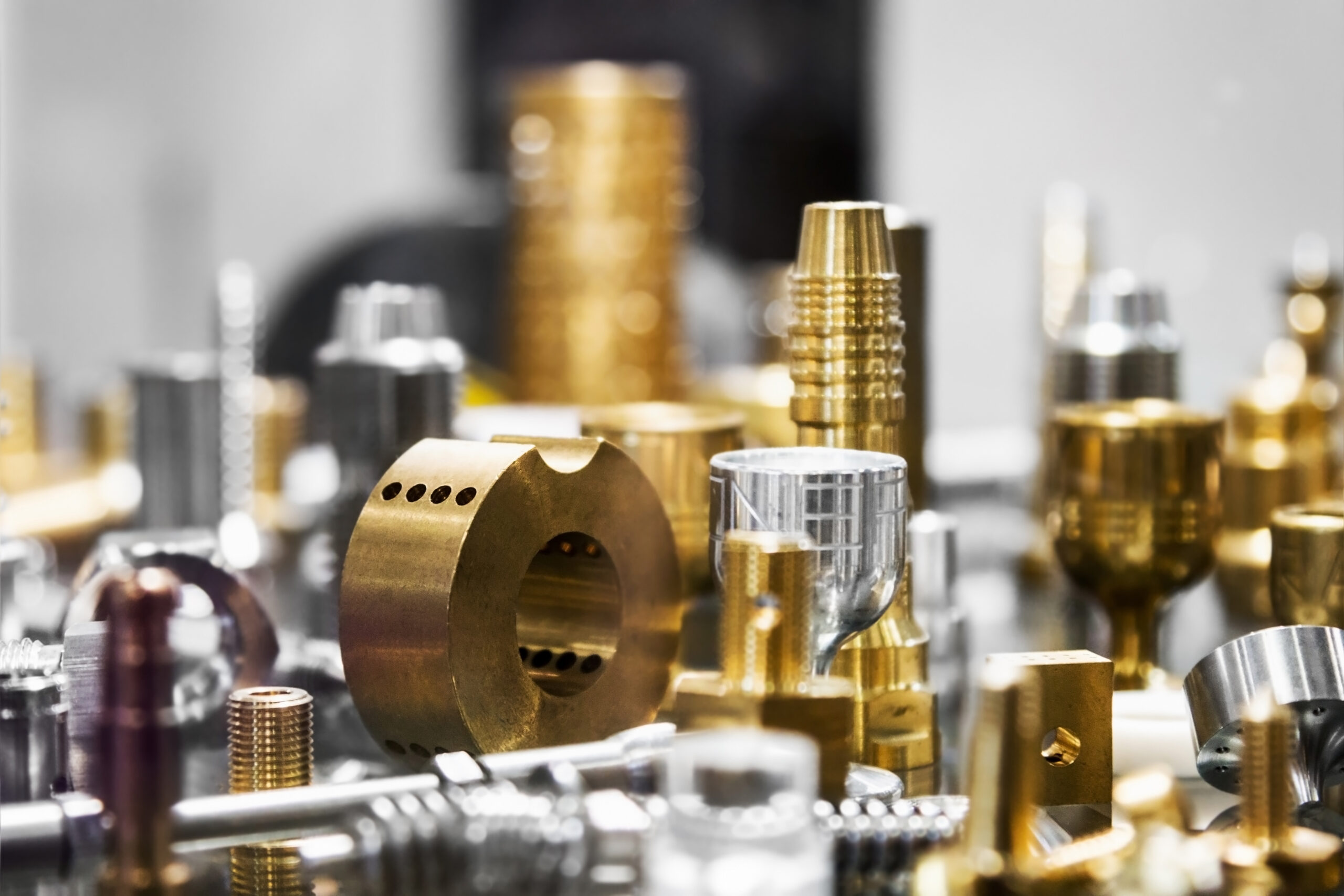

One of the many different types of CNC machining capabilities that Rapid Precision Manufacturing offers is horizontal machining. This type of machining center is especially suited to large scale production, designed to produce high precision parts at much faster rates than other machining centers, and at more efficient costs, especially for high production volumes.

What is a horizontal production machining center?

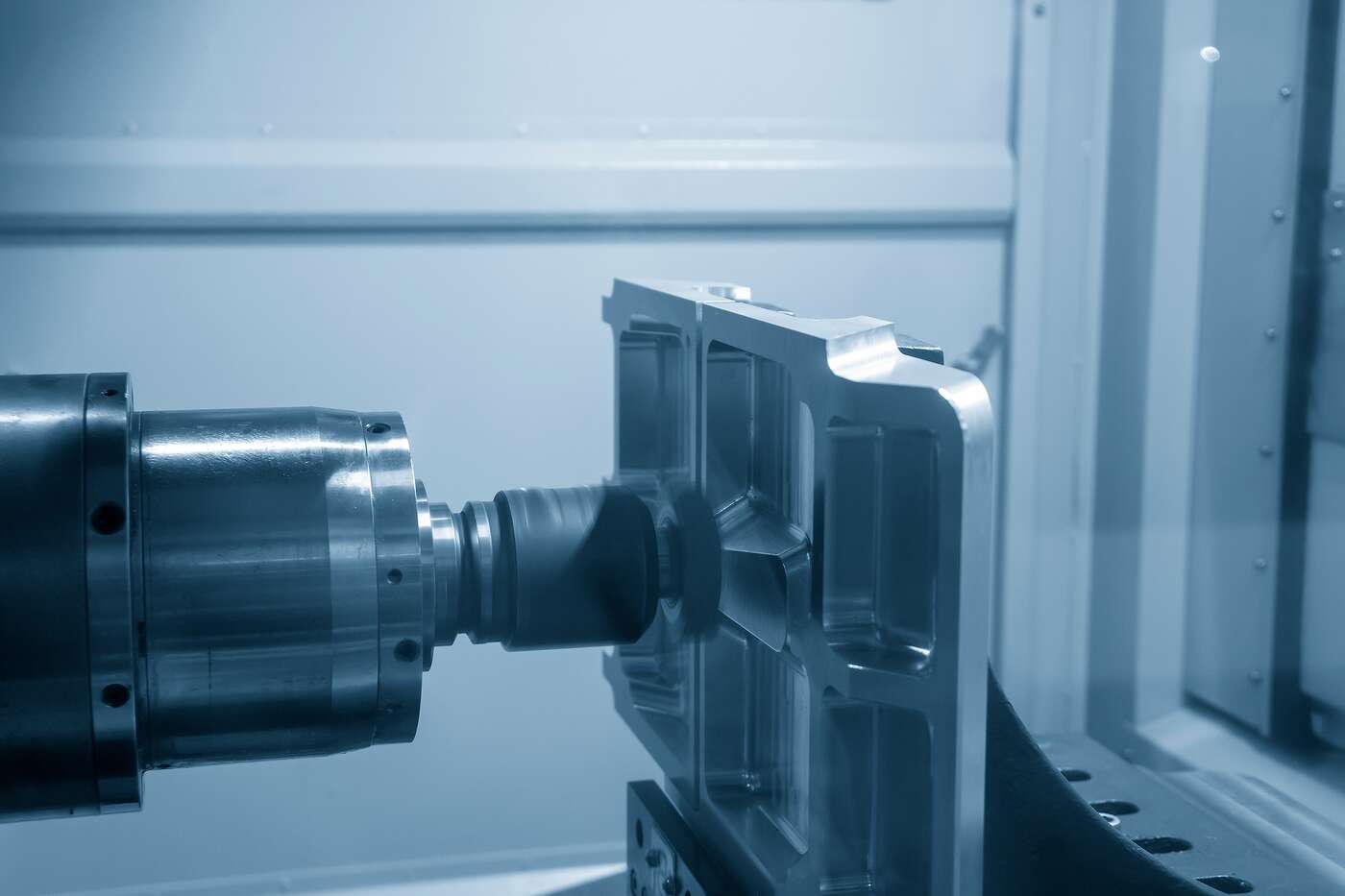

Horizontal machines feature a horizontally-oriented spindle, which holds the workpiece parallel to the work table. This allows for any chips generated during the machining to be more easily collected and removed from the area, which goes a long way towards improving the surface finish of the part. Horizontal machines tend to work on multiple axes as well, providing a way to produce multiple features on a part quickly and efficiently.

Improving Production Machining Efficiency at a Large Scale

Horizontal machining centers were designed for large scale production of parts with multiple features. The table moves horizontally and transversely to allow for milling on many different angles, and thanks to better chip evacuation, parts emerge with smoother surfaces. That means much less fabrication at the end of production to get the perfect dimensions and surfaces.

This type of machining center also tends to have a much higher load capacity, able to process multiple pallets of parts at once, and creating simple, high precision parts quicker as a result. The design of the center, combined with a good chip evacuation system, ensures simpler chip removal and prevents tool wear, breakage, and surface defects–all of which could cause downtime, increase the amount of time needed for production, and overall reduce production efficiency.

Some horizontal centers are even equipped with automatic tool changers, which can change tools more rapidly than manual tool changes, reducing downtime. The changes are controlled by the computer programs of the machine, and change happens the moment it’s time to go from one step to another. They are also used to change out worn or broken tools, and help to automate the machining process.

Are you in need of a precision manufacturer?

Rapid Precision Manufacturing, Inc. is your partner in precision, with proven machining expertise in a wide range of industries. Check out our website to learn more about how we can help you, and request a quote today.