An overview of CNC Turning and its applications

CNC Turning is one of the most widespread types of manufacturing, due to its production speed and accuracy. Like CNC milling, CNC turning involves shaping a workpiece by removing material from it, and thanks to its computer-guided tools, CNC turning machines can produce incredibly tight tolerances.

How does CNC Turning work?

Within the machine, the workpiece is held on a chuck and then rotated at speeds. A tool or tools are then fed to the rotating piece to remove material and achieve the desired shape. Common operations performed by CNC turning equipment includes boring, drilling, facing, grooving, knurling, and parting. While CNC Turning is not as good at conserving material as other operations, it’s much more versatile and allows for more complex design options.

Other benefits of CNC Turning include:

- Increased production speed and efficiency

- Cost-effectiveness

- Safer manufacturing operations

- Higher accuracy

- More operation flexibility

- High repeatability

The applications of CNC Turning

Because of its versatility and its production speed, CNC Turning has a wide range of applications in many industries. It’s often used to manufacture highly precise metal parts for the inner workings of vehicles and Automotive related applications. It’s also popular in prototyping because of its flexibility and the many types of operations available.

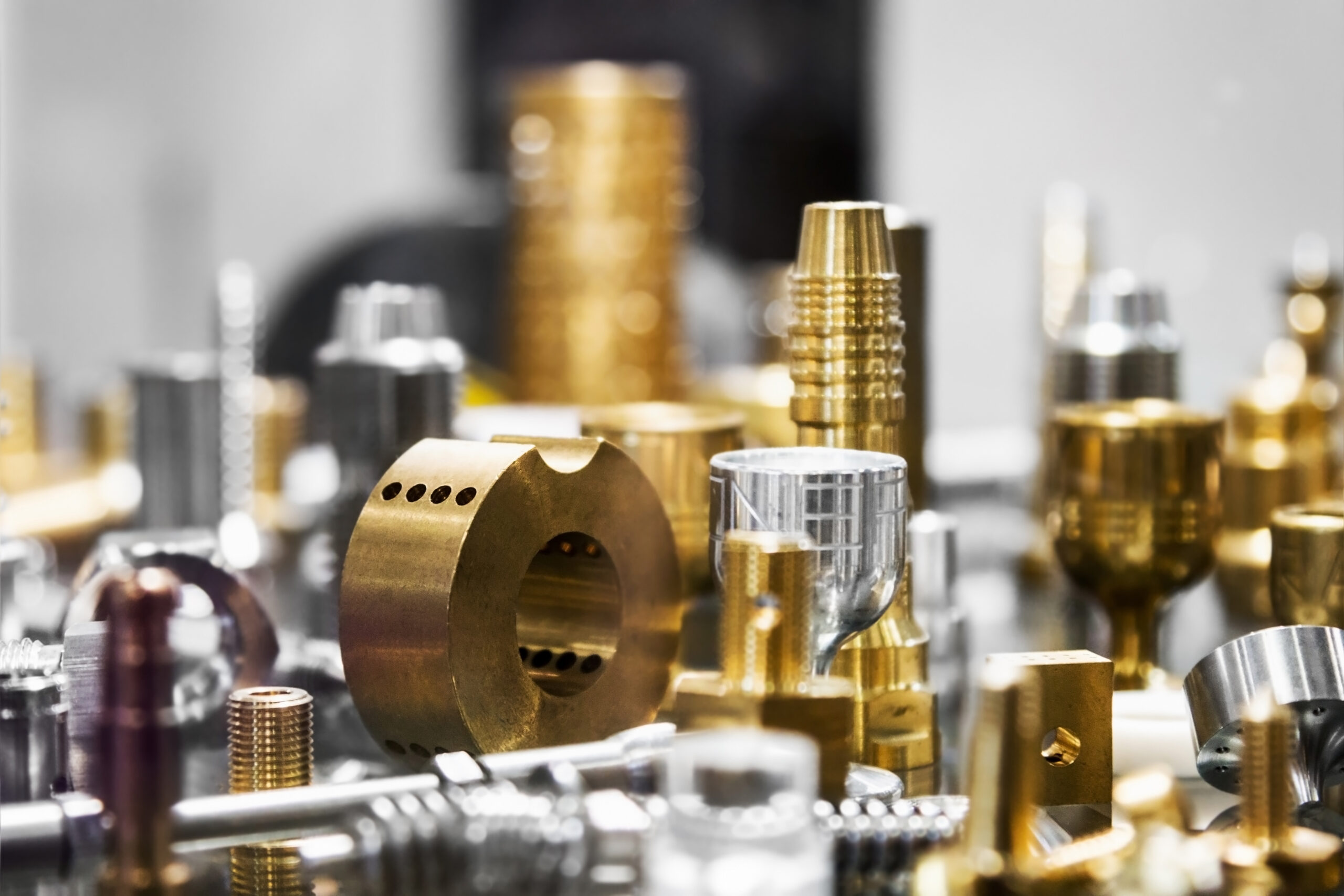

CNC Turning centers are most often used to machine parts that are rounded, or symmetrical on their axis, adding features such as holes, grooves, threads, tapers, and contoured surfaces. It’s mainly used to machine metals such as aluminum, alloy steel, stainless steel, and copper, to name a few, but it can also work with other materials as well.

Some common market applications include:

- Firearm components

- Industrial equipment components

- Mechanical components

- All-terrain vehicle parts

- Small metal components for electronics

Looking for a precision manufacturing company for your products?

Rapid Precision Manufacturing is your partner in precision when there’s no room for error. We have over a quarter century of experience in CNC turning and Swiss turning operations, and we offer several secondary and finishing services as well to provide you with finished, ready-to-use metal parts. For more information about RPM, check out our website today!