Over the past few decades, a certain type of lathe has seen more and more widespread use in precision CNC machining–the swiss-type lathe. Also known as swiss screw machines and swiss turning centers, swiss-type lathes are a unique type of machine originally dedicated to making tiny parts for watches. Because of their capacity for high precision and tight tolerances, swiss screw machines have become a popular type of CNC machining equipment across many different industries.

Swiss-type–how is it different?

Swiss style lathes are unique in their structure, because unlike in traditional equipment, the holding mechanism or collet is recessed behind the guide bushing. This ensures that the bar stock held within the machine is not directly exposed to the lathe bed and tooling. The guide bushing itself also improves the lathe’s performance. Through this mechanism, only a small amount of the workpiece is exposed, offering much higher rigidity to turned parts than other machine types.

The benefits of swiss-type machining

Because it was originally designed for the watch-making industry, Swiss machines are uniquely capable of producing extremely small and precise parts at a rapid pace. Because the workpiece is firmly supported throughout the operation, the part is virtually unaffected by the force of the tools. This ensures extremely tight tolerances even on small components, without worrying about undue stress on the parts themselves.

In addition to tight tolerances, swiss style lathes can also produce much more complex and intricate parts. Thanks to its design, this equipment can accommodate more delicate features and deeper cuts that aren’t possible on other types of machines.

Swiss style lathes can also offer faster production rates as well, with shorter turnaround times and more efficient processes. That, combined with the clean surface finish that often results from using Swiss machines means that parts are often ready to deliver right out of the machine.

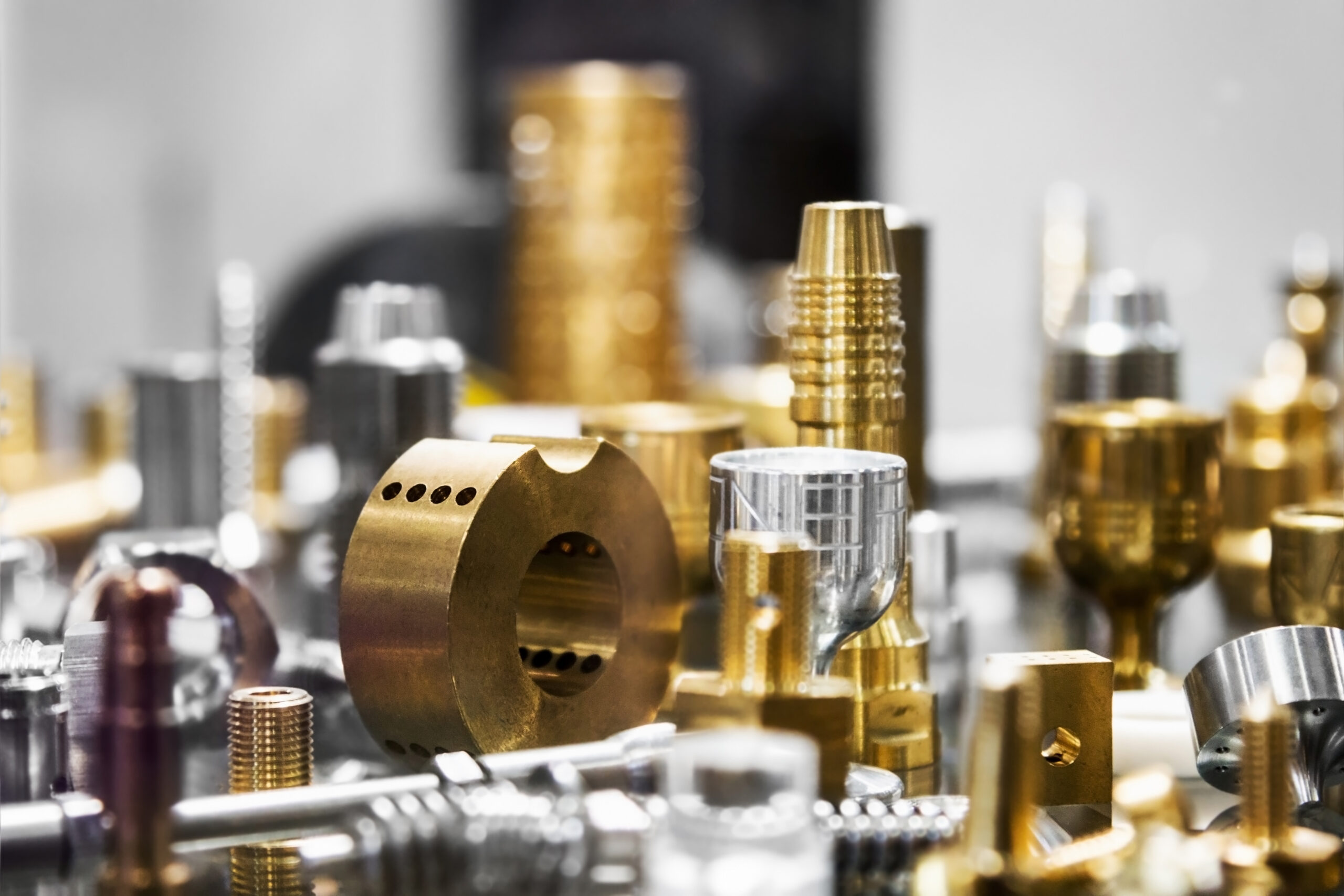

With all of these advantages, Swiss style lathes have quickly become popular across many different industries and for many applications, including firearms pieces, archery components, industrial and hydraulics equipment, and much more.

Looking for a precision CNC manufacturing company?

Rapid Precision Manufacturing, Inc. is your partner in precision CNC machining for a wide range of applications and industries. Check out our website to learn more.