A brand new iFP Parts Cleaner

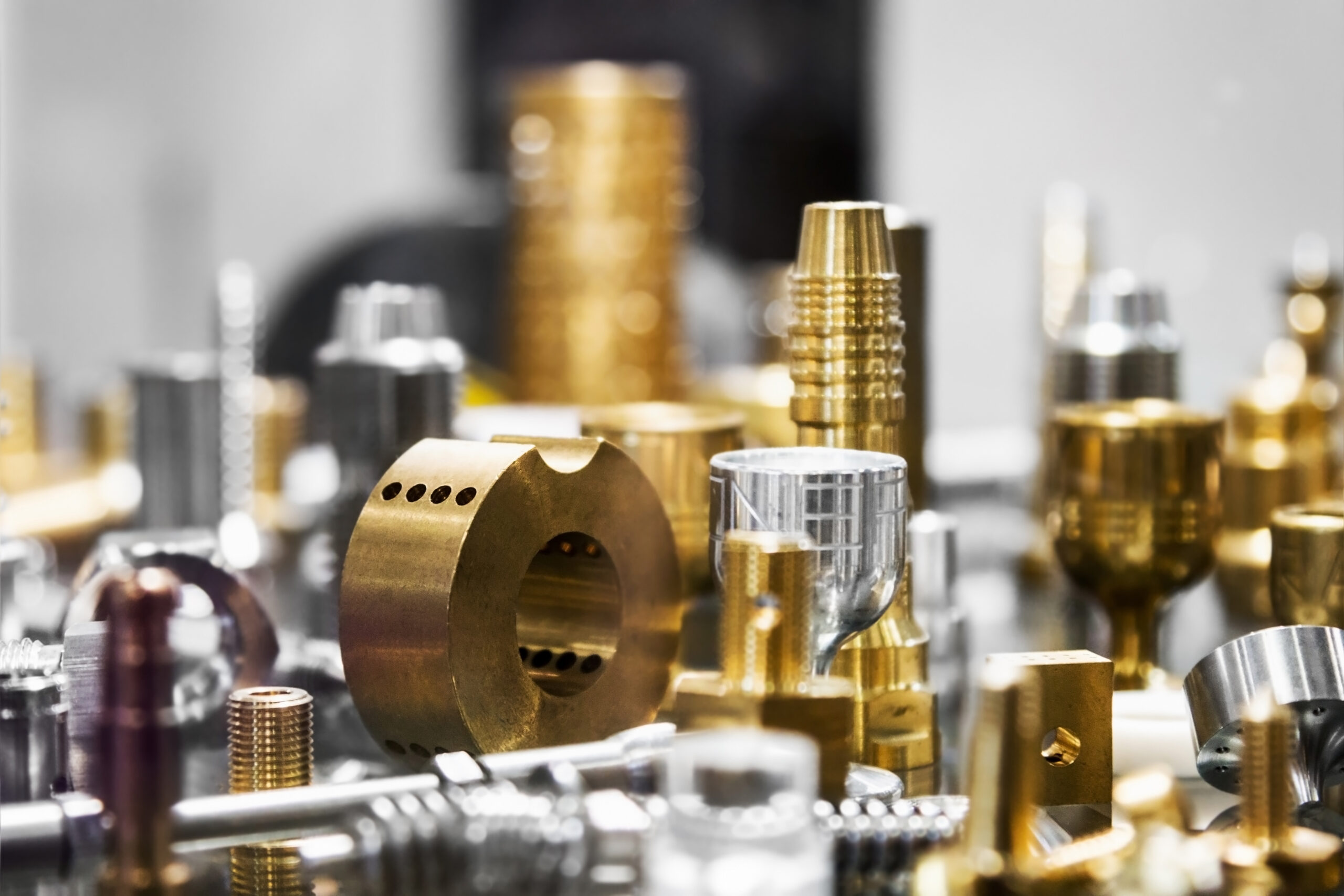

Rapid Precision Manufacturing (RPM) is proud to announce the addition of an iFP (Industrial Finishing Plants) KP.HMA 50 Parts Cleaner.

The KP (Kleen Power) vacuum parts cleaner offers the best technology on the market to provide a quality solution for removing oils, contaminants, shavings, and burrs from your part. Even difficult-to-reach part geometries such as blind holes, threads, and recesses are no problem for this machine.

Our efficiency is not only increased by its accelerated operation speed, but its solvent distillation and recovery system. The KP unit offers continuous solvent filtration and automatic distillation for separation of any contaminants, oil, and solvent.

This iFP has the added bonus of being environmentally friendly as well. It employs clean and green chemistry under vacuum to eliminate the use of hazardous or expensive solvents.

RPM invests in state-of-the-art equipment, such as the new iFP Parts Cleaner, in order to improve internal efficiencies and productivity. Our goal is to keep our customers’ costs low, while providing a quality, clean, part to your operation ready to use.

A new packaging and distribution center to coincide with our new iFP parts cleaner

In conjunction with the acquisition of our new Parts Cleaner, RPM’s larger facility has undergone a continuous improvement project. We’ve relocated our internal shipping area for better product flow, as well as a better organization of our inventory.

These enhancements will provide for improved productivity and customer order fulfillment.