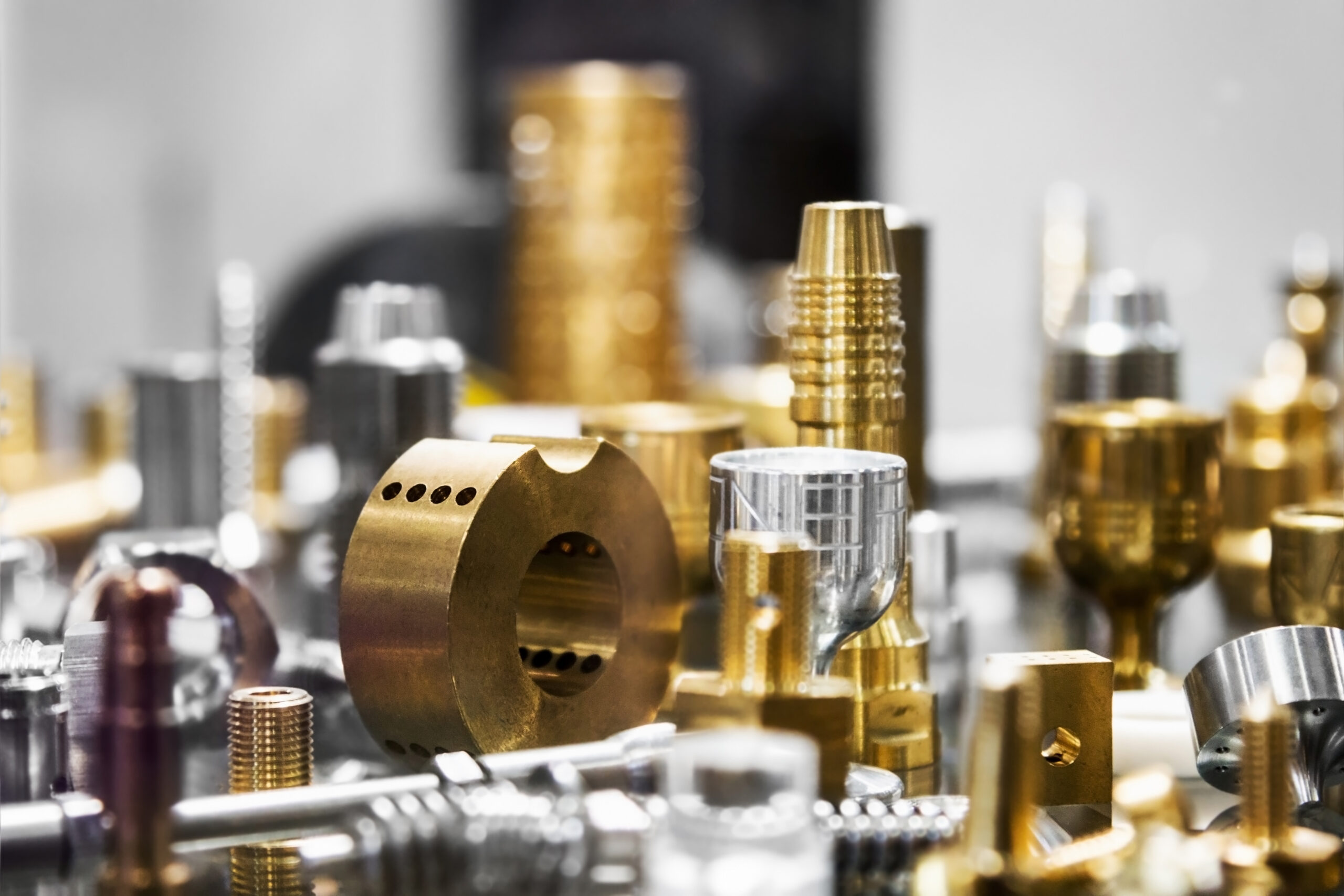

When it comes to the quality management process of precision machining, Accuracy and Precision are important, often interchanged words. However, these are two very different terms, each with their own bearing on the quality of the resulting parts. Today, we’ll discuss accuracy and precision, and why they are so important to quality precision machining.

Accuracy vs. Precision

Accuracy and precision are commonly used interchangeably in quality management, though they mean different things. Accuracy refers to how close a measurement is to the accepted value–so how close the dimension is to what’s specified in the design. Precision refers to getting the same or very similar results multiple times–how consistent the measurements are across multiple components. It is possible for a measuring equipment to have both accuracy and precision, neither, or just one of these qualities; however both are often vital to the performance of the manufacturing equipment and the parts that are safe and high quality.

There is also another part of precision that is important in precision machining, which is reproducibility, the precision that occurs when different operators use the equipment. There can be differences that occur between parts when two different people make measurements with the same equipment.

Accuracy, Precision, and Quality Management in Manufacturing

Precision CNC machines are vital in today’s world of manufacturing. Computer numerical control has enabled manufacturers to achieve a level of accuracy and precision that was not previously attainable. However, in order to ensure that machined components are both precise and accurate, the measuring has to be done in the same conditions each time in order to ensure that the measurements are consistently accurate, and to avoid deviations or errors.

There is also the importance of tolerances. This term refers to the range in which a certain dimension can deviate from the accepted value without affecting the performance of the part. There will always be slight differences across parts, though computerized precision machines produce far less deviance–as well as far more accuracy–than previously possible.

Why does this matter?

The precision and accuracy of your parts will often determine their performance and lifecycles. Well-made components, no matter the industry, will perform much better and for far longer than parts that aren’t accurate. Having precision across parts provides reassurance that each of these parts will maintain that longer life, keeping everyone safe and providing increased value.

Precision and accuracy are important for a wide range of product volumes. When it comes to prototyping, having precise, accurate components makes testing prototypes much more efficient. For high volume production, precision across tens of thousands of parts is vital to ensuring customer satisfaction and long-lasting quality.

Looking for a supplier of quality precision machining services?

Rapid Precision Machining delivers precision machining services with exceptional quality. To learn more, check out our website!