In several of our past articles, we’ve discussed the particulars of Swiss machining, and how this unique type of CNC turning compares to other manufacturing methods. Today, we’re going to explore when and why you should choose this option for certain types of precision manufacturing jobs.

What is Swiss Machining?

Before we go into the benefits and applications of swiss machining, let’s first get a quick refresher on what this service is. Swiss screw machining or Swiss turning is a type of manufacturing developed originally to make extremely small parts for watches. Swiss lathes, as these machines are often called, provide much stronger support for the workpiece, greatly reducing the amount of mechanical stresses introduced to the piece that could make the creation of finer features difficult. These machines also have the capability, due to the strong support of the guide bushing, to easily perform several operations at once for more complex designs.

The Benefits

The advantages of this process go beyond precision–though it is the advantage it’s known for. Swiss machines offer several benefits for both machinists and their customers, including the capacity to produce miniature components with high accuracy and efficiency. Because of its design, the Swiss lathe can perform multiple operations at once, improving lead times even on more complicated geometries and features. They also offer a higher level of precision than any other modern machining technique, and the machine’s overall design ensures that the part will not be damaged during operations. And most importantly, they can accommodate miniature components, which is especially important for industries looking to save space, reduce weight, or create more streamlined product designs.

When is Swiss Machining Most Beneficial?

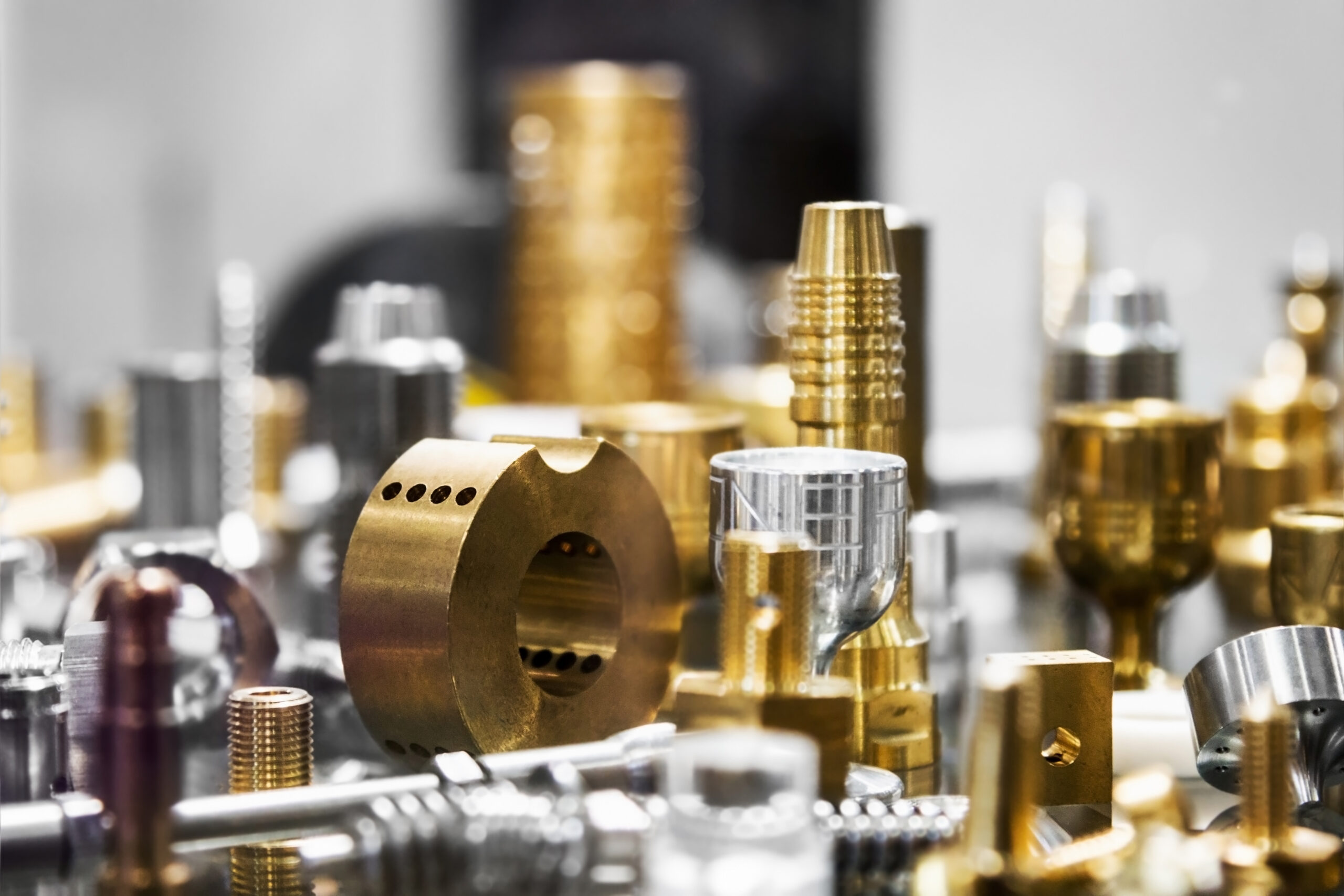

This option is best suited to parts that are smaller in size and require extremely tight tolerances. These lathes can accommodate a wide range of materials, such as copper, brass, aluminum, steel, and plastic, to make high precision components very quickly. Because of this, it’s a popular choice of machining for a wide range of applications, including but not limited to, firearm components, fuel systems, industrial equipment components, and much more.

Looking for an expert in Swiss machining?

Rapid Precision Manufacturing, Inc. is your partner for precision, offering a wide range of precision machining services with quick turnaround and excellent quality. Head over to our website to learn more about what we can do for you and request a quote on your next project!