Rapid Precision Manufacturing has grown significantly over the years, from our first projects of turning parts on our Haas equipment to our expansion into Swiss turning, multi-axis machining, and horizontal milling. We’ve chosen our name the same way that we’ve gained our reputation for quick turnaround on high-precision parts–by providing each and every customer with rapid machining services that meet their needs.

A wide range of rapid machining capabilities

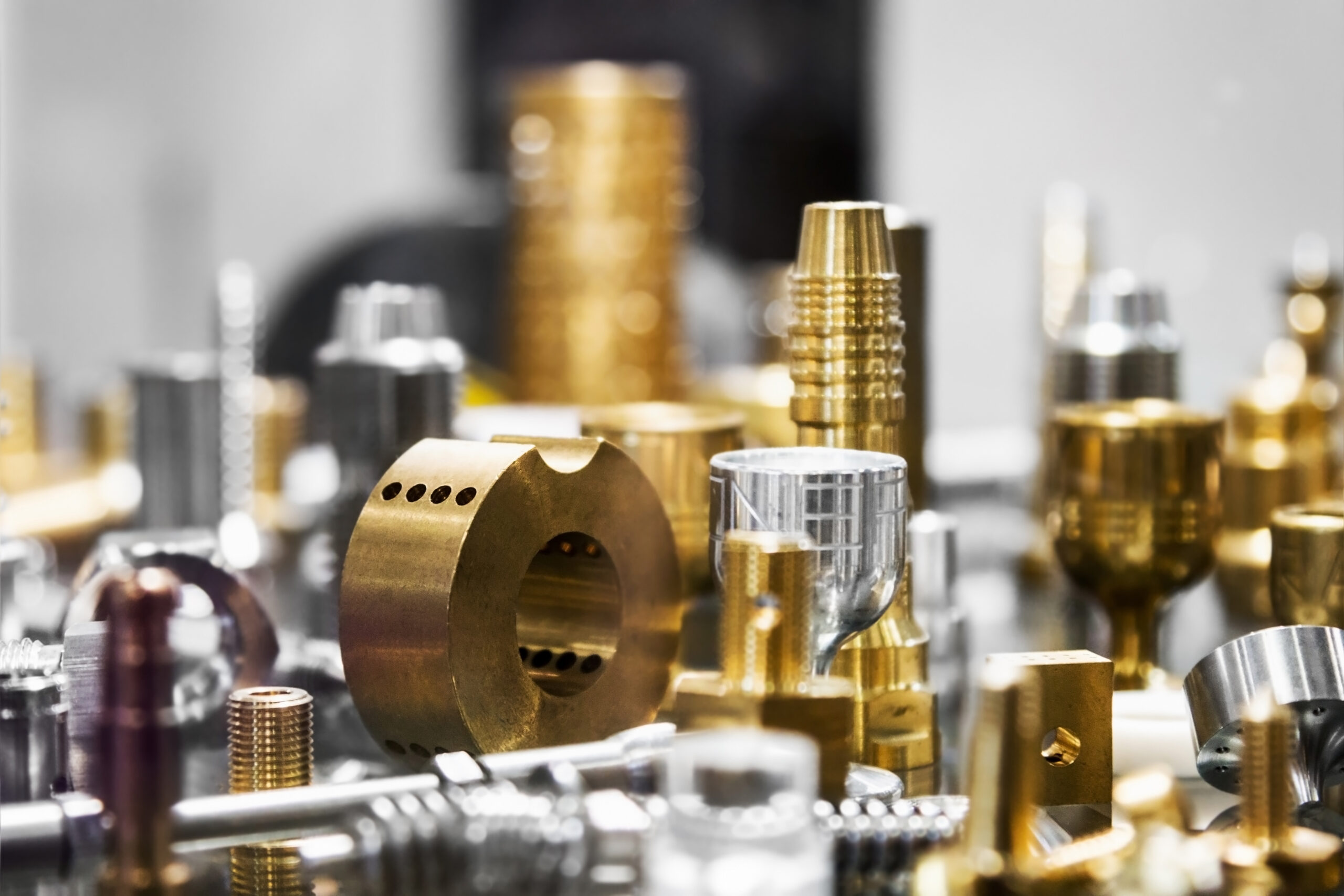

One of the things that sets us apart is our variety of rapid machining capabilities. We have several CNC lathes to perform turning, facing, grooving, parting, threading, drilling, tapping–basically any operation that it could possibly do. We also have Swiss lathes, the best in precision when it comes to CNC turning especially for very small, complicated components or tiny parts that have to meet extremely tight tolerances.

In addition, our facility houses a large number of CNC mills, from multi-axis machines to horizontal and vertical mills and more. Having all of these different machines allows us to make a much wider variety of parts in size, geometry, tolerance, and material.

In order to become a ‘one stop shop’, we also offer secondary and finishing operations, such as vibratory finishing, deburring, reaming, plating, E-coating, powder coating, and anodizing. This way we can provide the full package from machining to finishing without our customers having to outsource all of the different operations. This reduces both the time it takes to deliver a finished product and even the overall production costs–after all less outsourcing means less money spent on shipping.

A focus on quality

We take a thorough, proactive approach to quality when it comes to our rapid machining services. That includes regularly spot checking random part samples, upholding our compliance with ITAR, and maintaining a quality management system certified to ISO 9001:2015 standards. We’ll carefully analyze each part design and specifications to ensure both design for manufacturability and what materials and processes will fulfill each project’s needs. And we also have a wide range of equipment to evaluate and quantify the quality of each part, ensuring that they meet our and our customers’ stringent requirements.

Rapid response from RFQ to part delivery

Rapid Precision Manufacturing takes pride in dutifully responding to your RFQ and quickly responding with a competitive quote if the part fits our capabilities. We work with the customer to clarify any questions or concerns related to the drawing and manufacturability of the part. Once your order is placed, we strive to promptly put in place all necessary quality documentation, order materials and tooling, and schedule your part for production. We seek to timely schedule, produce, and deliver quality parts that meet customer expectations, on-time, and within budget.

Looking for a provider of rapid machining services?

Consider working with Rapid Precision Manufacturing! We have one of the widest ranges of machining capabilities in the industry and a strict focus on quality and customer satisfaction. Head over to our website to learn more and request a quote today.