If you’ve interacted with the manufacturing industry in some way, you’ve probably heard the term ‘swiss machining’ thrown around. Swiss machines are a fairly recent (compared to other types of machining) advancement that was made even better by computer numerical control. Though this modern precision manufacturing machine was originally designed to manufacture small, delicate parts of watches, it exploded into popularity throughout precision manufacturing.

CNC Swiss Machines–a new type of CNC lathe

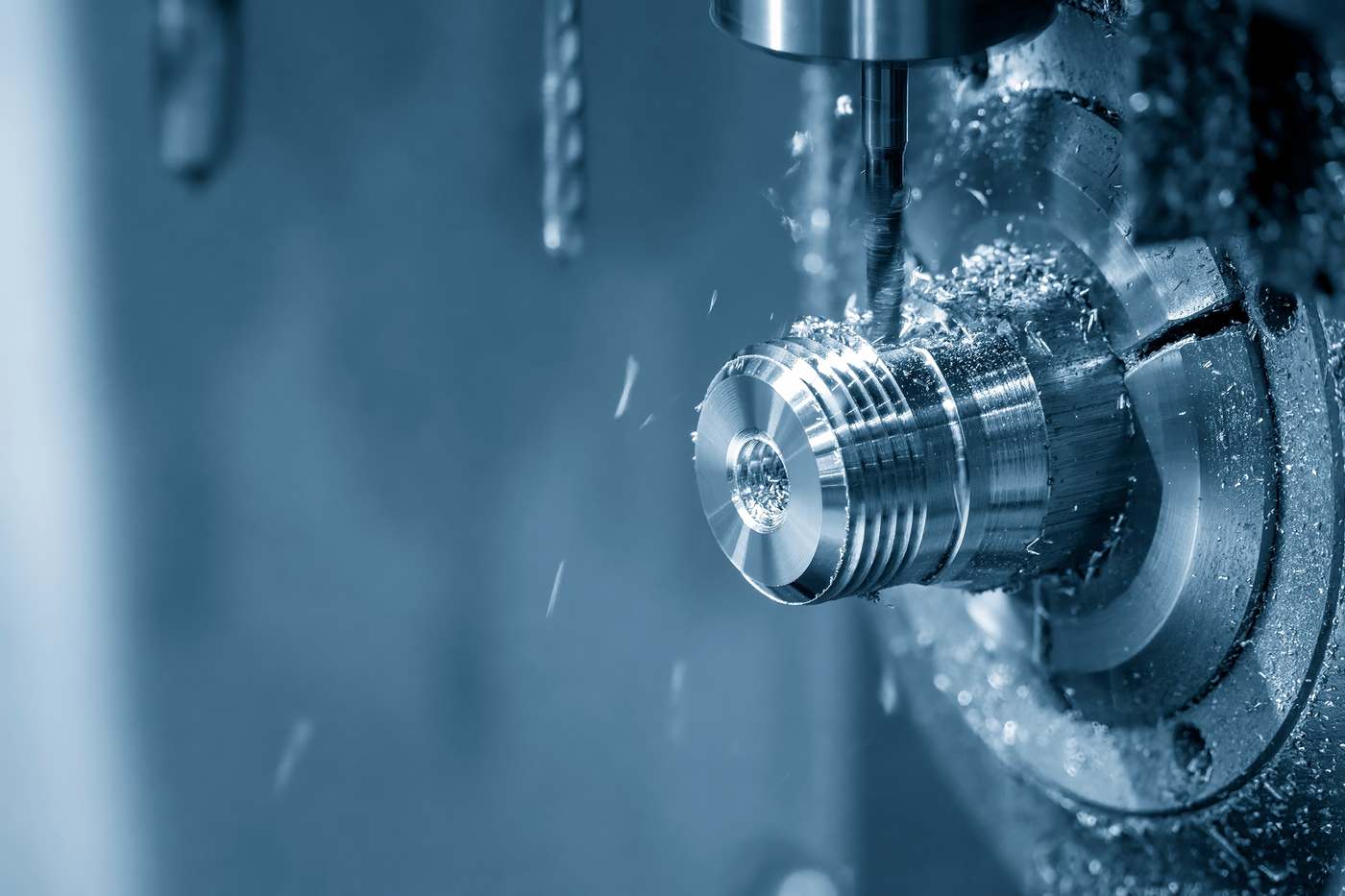

CNC Swiss machines, also known as Swiss-type lathes or Swiss automatic lathes, are a type of precision manufacturing equipment. Like other CNC machines, the machine feeds bar stock through the tooling area, while keeping the stock secure and stable. The workpiece is then rotated rapidly against the tool in order to remove material and achieve a desired shape.

Swiss machines are more flexible however, as they can securely move the workpiece back and forth across the Z-axis while multiple different tools cut away material.

The Benefits of CNC Swiss machines

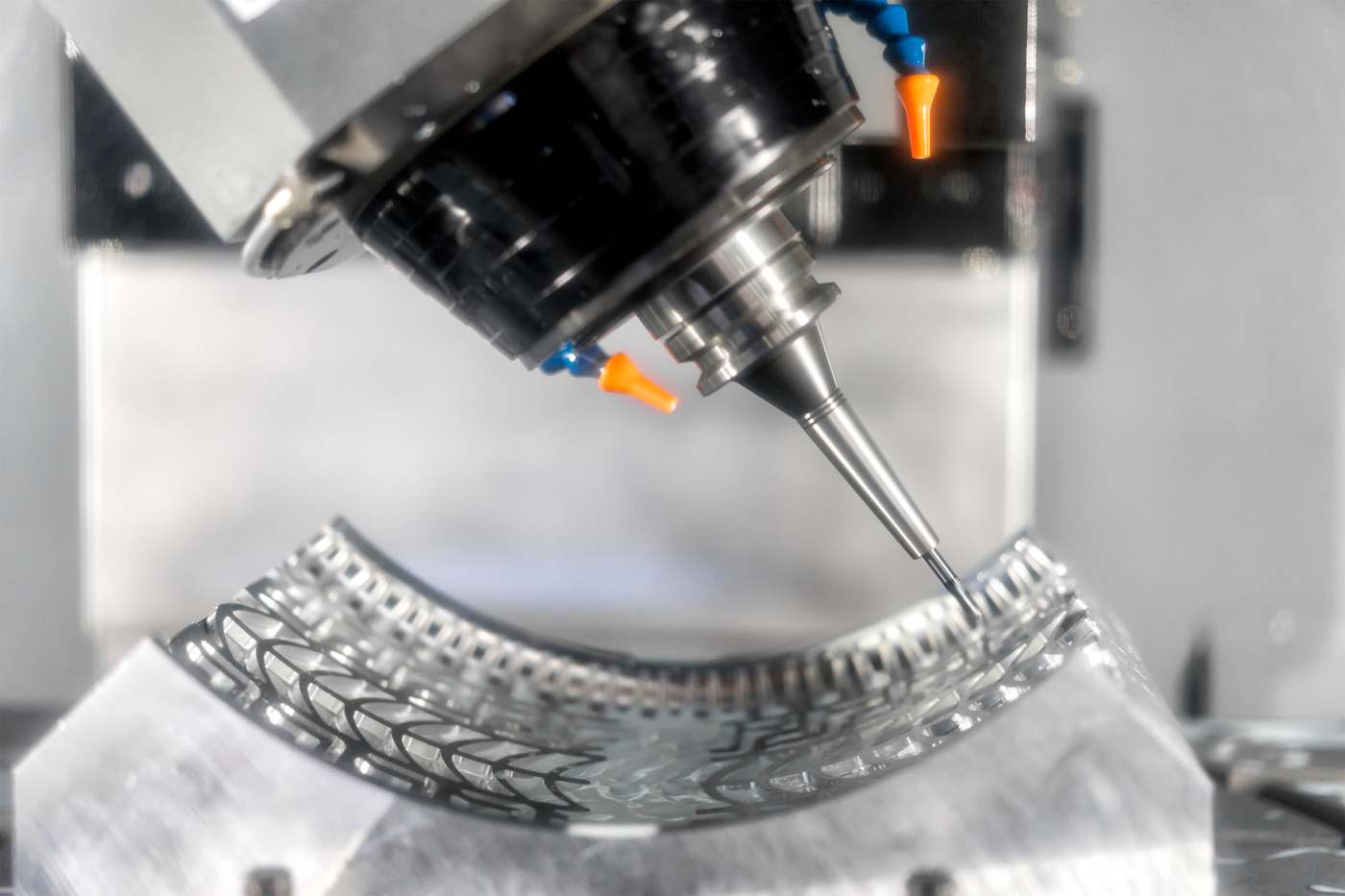

Though Swiss machines were originally used to machine turned pieces like screws, they are incredibly versatile and can also be used to manufacture complex pieces with no turned surfaces at all.

CNC Swiss machines are especially suited for machining exceptionally small, complex parts at high volumes. Due to its versatility, as well as the capability to perform multiple operations at once, these machines are also more efficient and quicker than normal CNC lathes.

Some other benefits include:

- Extremely tight tolerances, with little margin for error, even in very small and intricate pieces. Due to the machine’s support of the workpiece throughout the operation, the part always remains steady and is unaffected by the force of the operations.

- Finished parts, to the point where many will be ready to be shipped almost as soon as they are out of the machine. Swiss machines can produce such precise results that they often eliminate the need for secondary operations.

- Increased production efficiency, due to the significantly fast pace of the machine’s operation, as well as its ability to produce finished products. Overall, swiss machines can increase production of small, intricate parts, while reducing overall production costs and time.

CNC Swiss machines have a variety of applications across industries. From small, intricate implants to parts for medical instruments, even to tiny aerospace components, these machines are great for the most critical aspects of many types of equipment.

Looking for a supplier of CNC Swiss turning services?

Rapid Precision Manufacturing, Inc. is your partner in precision machining. We have a variety of precision manufacturing capabilities, from CNC Swiss turning to CNC milling, horizontal machining, and several secondary operations. Our Swiss machines can machine parts as big as 32mm in diameter. We offer some of the highest accuracy rates across several industries in product quantities from 10 to 100,000. For more information, contact us today!