If you’ve ever been involved in the manufacturing industry in some way, then you probably already know what precision machining is. However, if you’re new, or you need a refresher, then we’ve got you covered! This new blog series, Machining Basics is exactly what it sounds like–we’ll be outlining the basics of the different machining processes as well as the benefits of each.

In this first post of the series, we go over the basics of precision machining.

What is precision machining?

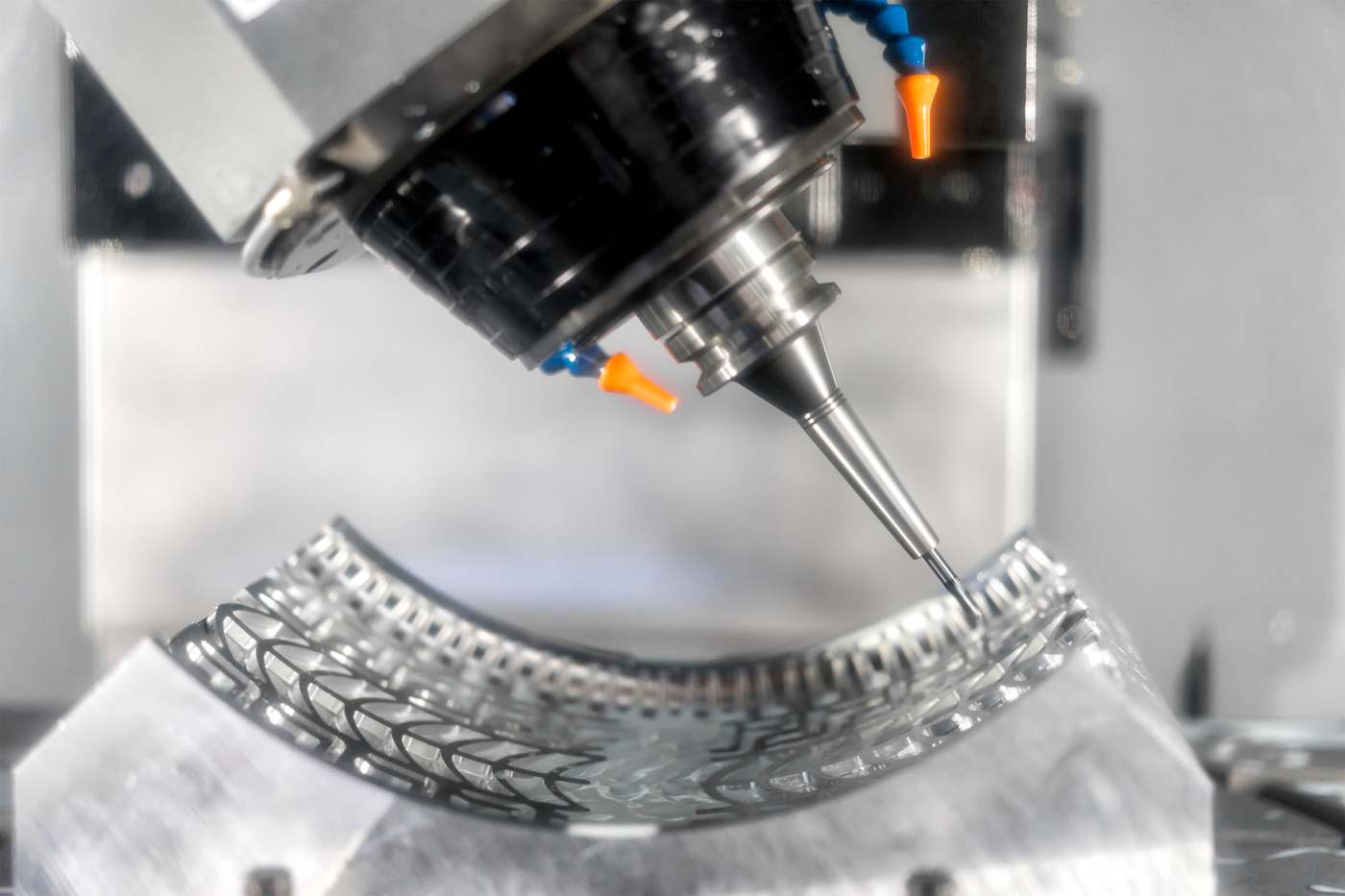

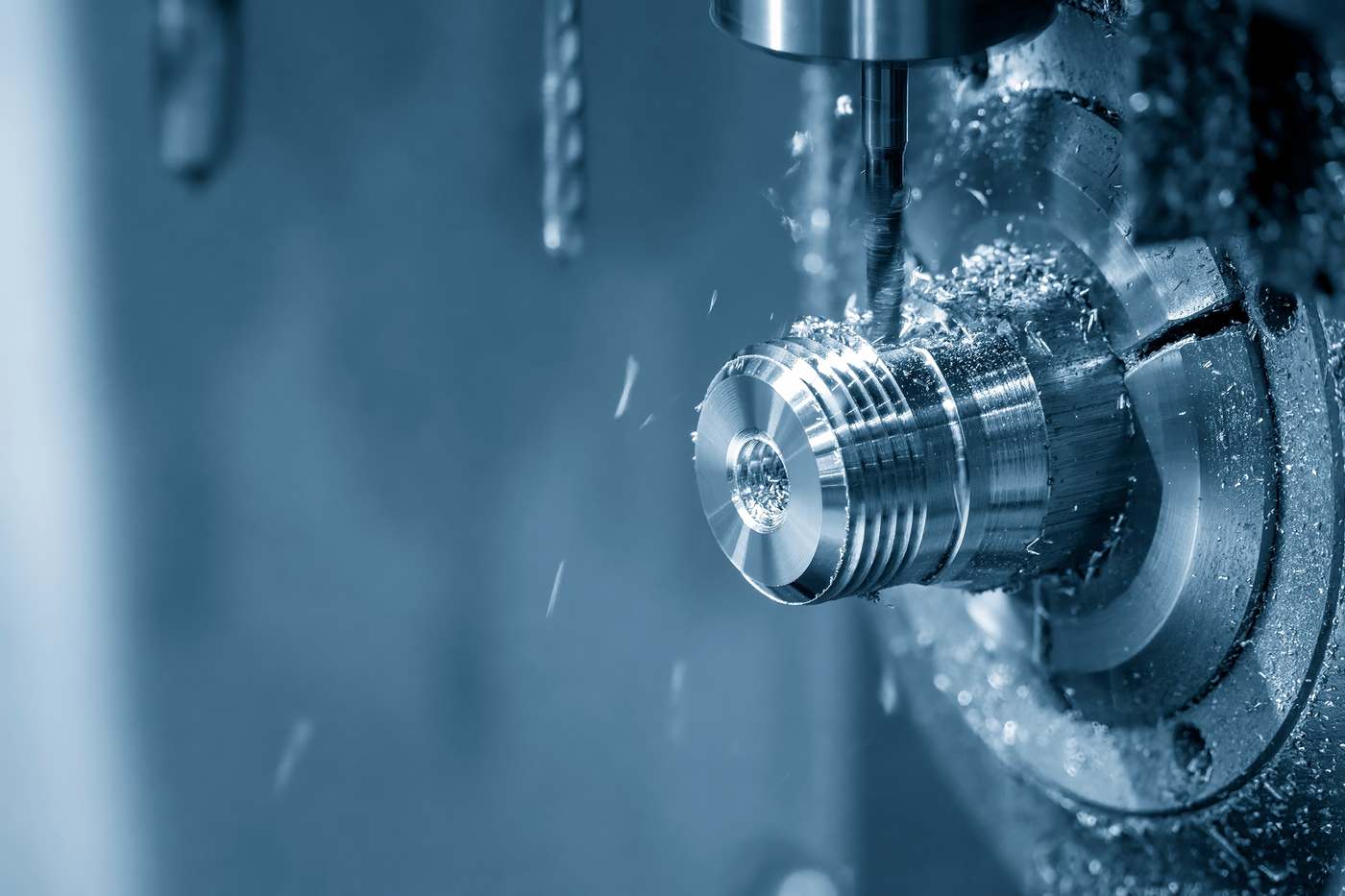

Precision machining is just the shaping of large pieces of raw material into smaller, more accurate parts in order to meet very exact specifications. Precision machining includes processes like cutting, milling, turning, drilling, and EDM–all of which shape a component material by removing excess material.

Over the years, as technology has advanced, so have precision machining processes. These days, ‘precision’ machining always implies the use of computer numerically controlled (CNC) equipment behind the process. Computer numerically controlled equipment machines parts with more precision and consistency than manual machining. Parts can be machined up to tolerances unattainable by manual machining, and at far greater consistency and efficiency as well.

The benefits of precision machining

From tools and welding equipment to surgical devices and aircraft parts, the benefits of precision machining can be found in every industry. Almost all of the technology in our everyday lives–vehicles, appliances, electronics, and more–is the result of precision machining.

CNC precision machining is an excellent tool for any project. As mentioned above, it can create tighter tolerances, producing parts with tolerances as small as ±0.0001, and it can do this consistently with little to no errors between parts. A lot of CNC equipment can also handle a range of production volumes, from small, prototype runs to high-volume production.

Precision machining is also a highly versatile process, able to manufacture simple and complex parts from a variety of materials such as:

- Aluminum

- Brass

- Various types of steel

- Copper

- Various plastics

- Bronze

- Stainless steel

- Metal alloys

- Titanium

Precision machining is also a much safer, and more cost-efficient manufacturing process overall. Operators can safely run the equipment from the machine interface, and the accuracy of the CNC controls makes for less waste, less downtime, and higher quality products.

Looking for a partner in precision machining?

Founded in 1997, Rapid Precision Machining has the technical and operational expertise to handle a range of product complexities and tolerances, as well as production capacities from 1 to 100,000 units. With over a quarter century of machining expertise, and a focus on CNC turning, RPM delivers fast, precise parts to companies in industries ranging from agricultural and filtration components, to firearms and industrial equipment. For more information on how we can serve you, check out our website today.